Permanent way monitoring

Safety and optimization of preventive maintenance are priorities for IEME Brasil and LAEDE when it comes to evaluating their customers’ metro rail systems. To achieve this, the company relies on cutting-edge technologies and methodologies, the result of exchanges and monitoring of studies in some of the most advanced technological centers on the subject. One of the resources adopted by IEME for this purpose is the instrumented wheelset calibrator, studied in Italy by the Università degli Studi di Firenze, Sapienza in Rome and the Polytechnic of Milan, institutions visited by the company.

But what is the instrumented wheelset calibrator?

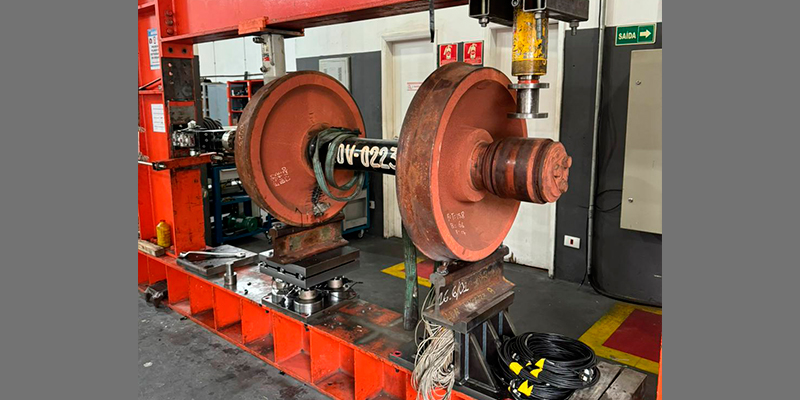

“The calibrator is a bench designed to apply existing loads on the permanent track onto an instrumented wheel set with the aim of correlating wheel-rail contact forces and deformations. To this end, electrical resistance strain gauges, hydraulic jacks, actuators and various load cells are used, in addition to a structure capable of supporting such loads”, explains engineer Tiago Juliani, Engineering coordinator at IEME Brasil.

There is a variety of information obtained by the calibrated instrumented wheelset. With the passage of the instrumented wheelset, the wheel-rail contact forces and the L/V relationship (lateral force / vertical force of the wheel) are obtained along the entire path of the train, which may indicate problems both on the permanent track as well as in the rolling stock, such as geometric imperfections in the track, welding defects, failures in railway components, poor maintenance of tracks and wheels, among others. Furthermore, the operational risk of the line is assessed with the L/V ratio.

Therefore, the calibrator is adopted whenever a new measurement campaign is carried out with the instrumented wheelset and, if the same previously instrumented wheelset is used, there has been a certain mileage between one campaign and another.

Read more

Inmetro revalidates IEME Brasil accreditation for inspection of road and rail projects The National Institute of Metrology, Quality and Technology (Inmetro) has just concluded its annual audit and revalidated the status of IEME Brasil Accredited Inspection Body (OIA), obtained at the...

Forced vibration dynamic test Do not panic. It's not an earthquake. This is Vibrodina at work in...

New instrumented wheel set IEME service Professionals and companies in the metro-railway area know that the most efficient and complete technique for determining the contact forces between the wheels of a railway composition and the track...